Articles Service

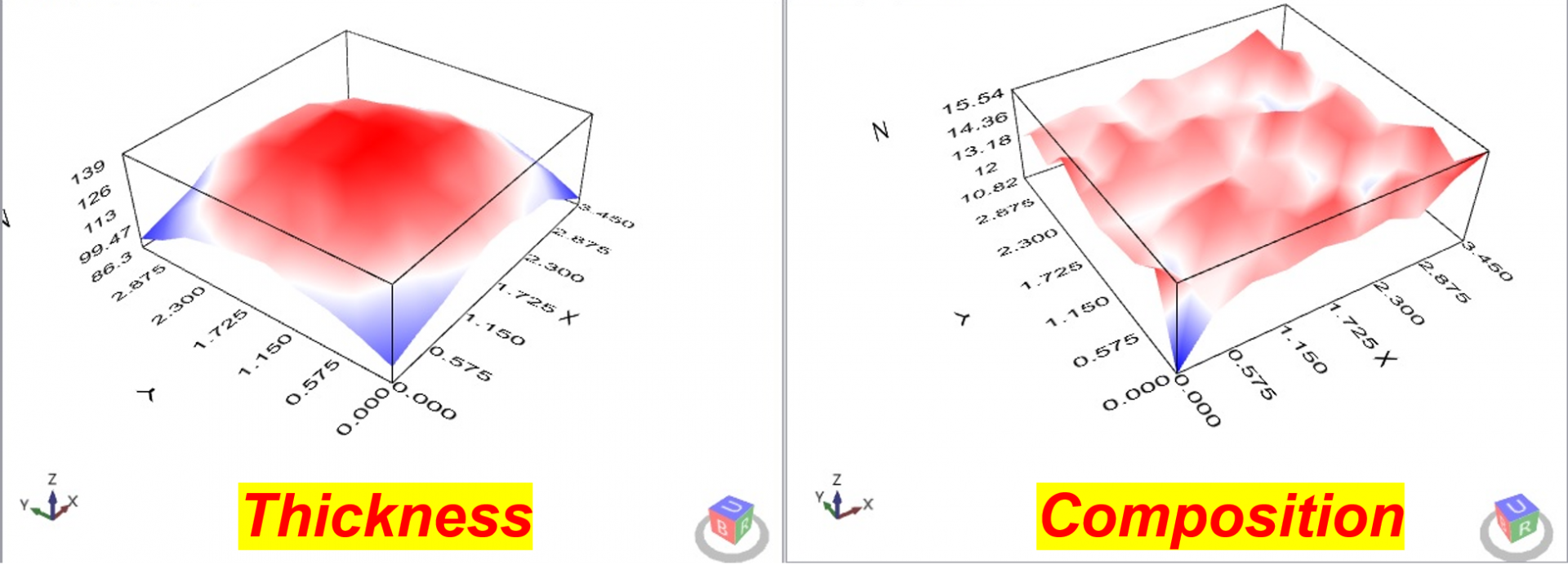

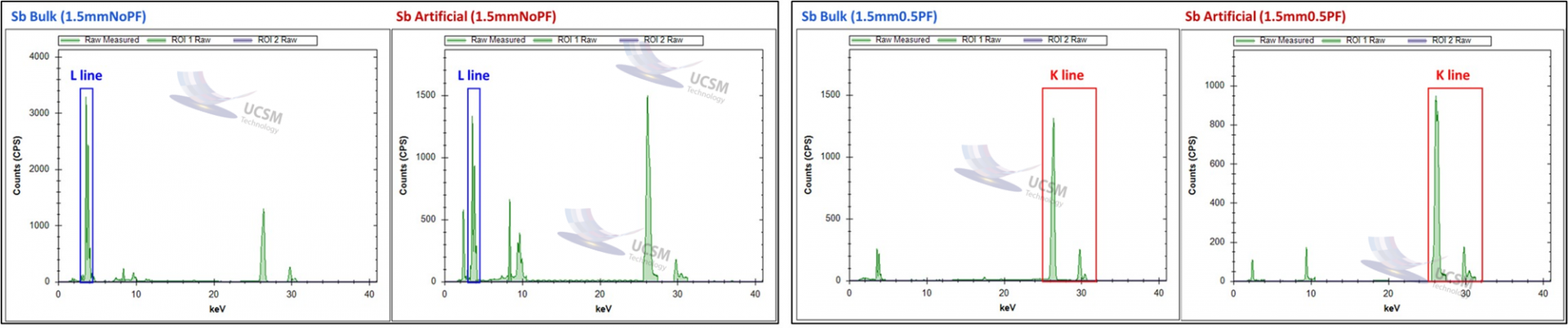

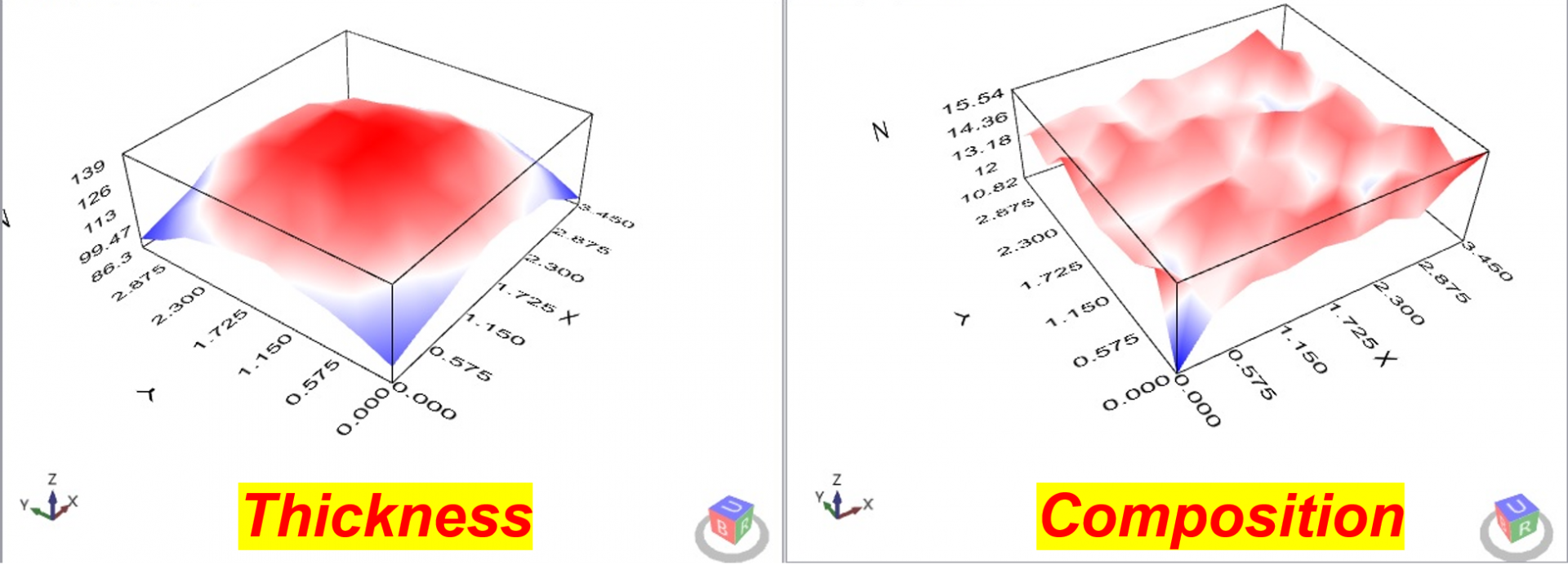

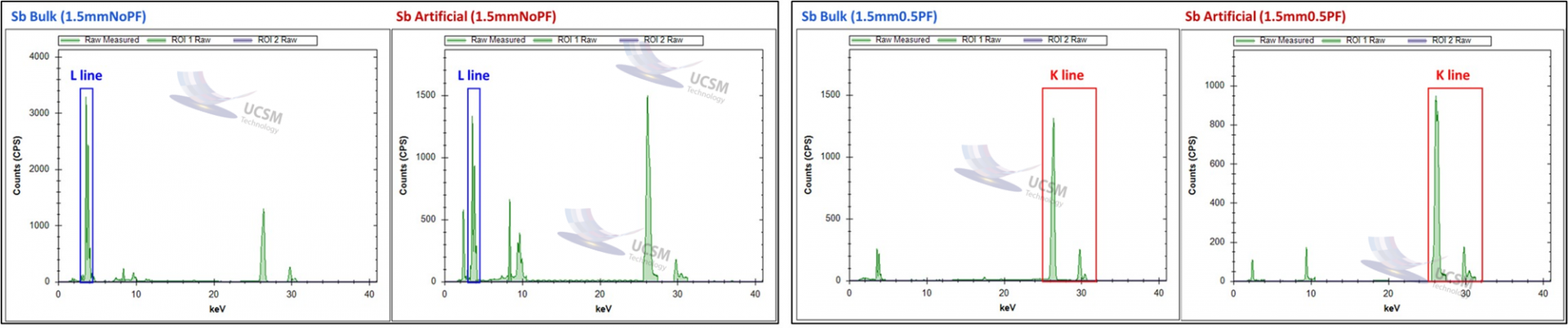

Thin film thickness and component XRF analysis

Film XRF Thickness and Composition Analysis Service

X-ray fluorescence spectroscopy (XRF) is a non-destructive chemical analysis technique that can quickly and accurately determine the types and amounts of elements in a sample. The technique is based on the principle that when a sample is irradiated with X-rays, the atoms in the sample are excited and emit X-ray fluorescence spectra. XRF analysis instruments typically include an X-ray generator, sample stage, X-ray fluorescence counter, and spectrum analyzer. The specific operation process is to place the sample on the sample stage, generate a beam of high-energy X-rays with the X-ray generator, irradiate the sample surface, and collect and convert the fluorescence X-rays through the fluorescence counter. Then, the fluorescence X-rays enter the spectrum analyzer for analysis. The spectrum analyzer separates the fluorescence X-rays by energy, measures their intensity and energy, and determines the types and amounts of elements represented by the fluorescence X-rays. The energy of fluorescence X-rays for each element is fixed, so by measuring the energy and intensity of fluorescence X-rays, information on the types and amounts of elements in the sample can be obtained. XRF analysis has the advantages of fast analysis speed, high accuracy, and no sample pre-treatment, and is widely used in fields such as metallurgy, mining, materials science, and environmental monitoring.

XRF Film Analysis

X-ray fluorescence spectroscopy (XRF) is a non-destructive chemical analysis technique that can quickly and accurately determine the types and amounts of elements in a sample. The technique is based on the principle that when a sample is irradiated with X-rays, the atoms in the sample are excited and emit X-ray fluorescence spectra. XRF analysis instruments typically include an X-ray generator, sample stage, X-ray fluorescence counter, and spectrum analyzer. The specific operation process is to place the sample on the sample stage, generate a beam of high-energy X-rays with the X-ray generator, irradiate the sample surface, and collect and convert the fluorescence X-rays through the fluorescence counter. Then, the fluorescence X-rays enter the spectrum analyzer for analysis. The spectrum analyzer separates the fluorescence X-rays by energy, measures their intensity and energy, and determines the types and amounts of elements represented by the fluorescence X-rays. The energy of fluorescence X-rays for each element is fixed, so by measuring the energy and intensity of fluorescence X-rays, information on the types and amounts of elements in the sample can be obtained. XRF analysis has the advantages of fast analysis speed, high accuracy, and no sample pre-treatment, and is widely used in fields such as metallurgy, mining, materials science, and environmental monitoring.

XRF Film Analysis