Articles Products

Ultra Clean Surface Machining

Ultra Clean Surface Machining Equipment

UCSM Technology is committed to solving the problems of damage, residual particles, cross-contamination, and oxidation caused by traditional surface processing methods of targets. UCSM Technology has developed an innovative sputtering processing technology to solve various surface problems of targets, providing target users with a good experience. Target users can enjoy the following benefits:

- 1. Shorten the pre-sputtering schedule to achieve producibility conditions earlier, and improve equipment OEE.

- 2. Improve the initial yield of thin films (product yield).

- 3. Reduce abnormal discharge behavior (arcing) during the sputtering process.

- 4. Significantly improve the adhesion of target splatter, and reduce the number of particles.

- 5. Have a more stable sputtering voltage at the beginning of the equipment operation.

- 6. Slow down the oxidation of the target.

- 7. Before the target is placed on the machine, users can use the sputtering data of the UCSM process to know if the target has problems in advance, avoiding abnormal target placement and greatly reducing the chance of abnormalities, saving various costs related to the loss of yield.

Who is suitable for purchasing this equipment?

Target manufacturers:

By pre-processing targets with the UCSM process before shipping, target quality competitiveness can be improved, and UCSM sputtering data can be used as a basis for abnormal interception and in-house product improvement.

Thin film manufacturers:

After receiving the target, thin film manufacturers can use the efficient UCSM process offline before placing the target on the expensive mass production machine to remove various dirt or contaminants in advance, improving the utilization rate of expensive equipment and ensuring stable initial quality of thin film production.

Target PM manufacturers:

After PM in the middle of target use, it often takes a long time to achieve stable product production at the beginning of the operation. By using the UCSM process to pre-process the target after PM, more time can be saved and the characteristics of the target can be improved.

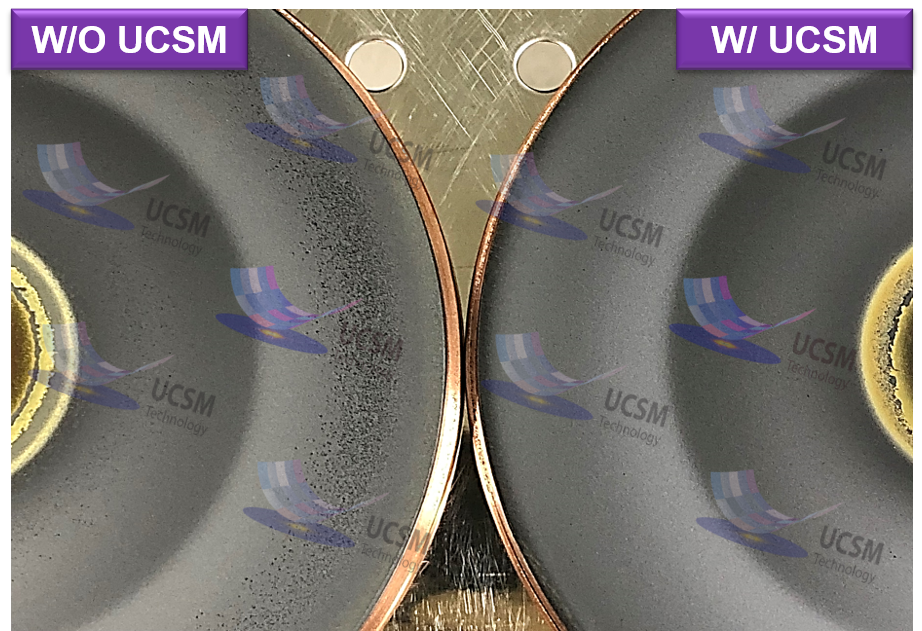

Nodule performance of ITO targets without and with UCSM process

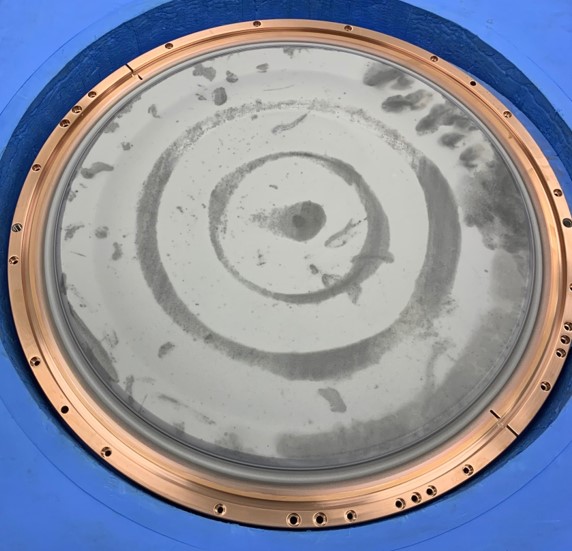

Appearance of the spent target after treatment by UCSM